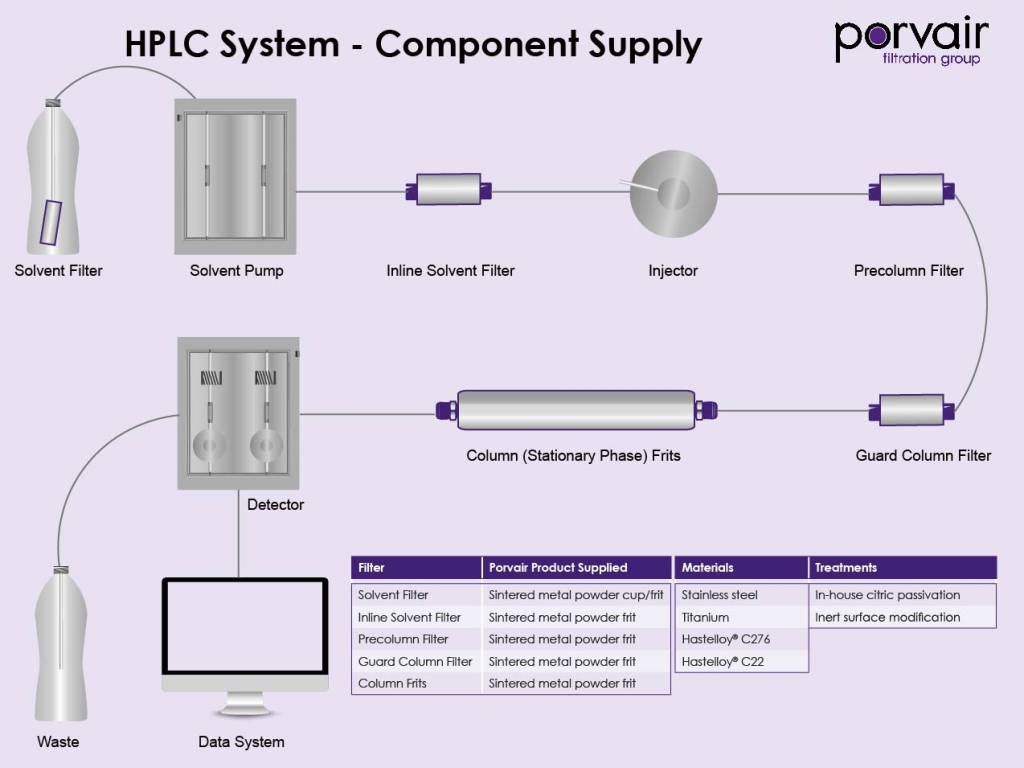

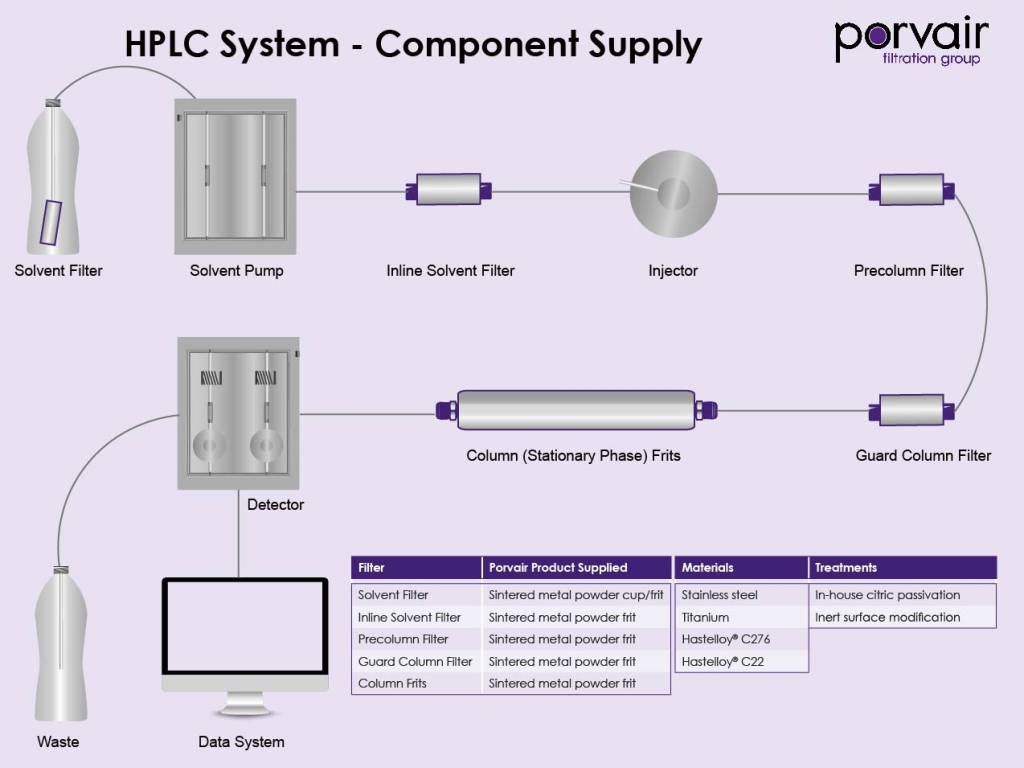

Porous materials for HPLC (High performance liquid chromatography)

Porvair manufacture sintered metal powder frits and cups used within the HPLC and UPHLC equipment.

These include column frits and solvent filters in materials such as Stainless Steel, Titanium, Hastelloy C276 and Hastelloy C22 and are available in a variety of pore sizes.

Column Support Frits

Purpose

- Retain packing material at both ends of the liquid chromatography column.

- Provide uniform flow of sample into column.

Features and Benefits

- Precisely fit customer’s dimensional requirements

- Withstand high-pressure applications.

- Passivation offered for corrosion resistance.

- With or without chamfer

- Inert (Titanium frits for bio columns)

- Can be supplied as a disc or press-fit into ring (often PEEK)

HPLC Solvent filters

Inlet solvent filter (sinker), inline solvent filter, pre-column filter and guard column filter

Inlet solvent filter

Purpose

- Protect HPLC pump inlet check valves from particulate.

- Function as a sinker to hold the pump inlet tubing to bottom of solvent supply.

- Removes the need for a pre-filter.

Inline solvent filter

Purpose

- Protects the sample injection valve from naturally occurring seal wear.

- Prevents downstream damage to components.

Pre-column filter and Guard column filter

Purpose

- Traps particulate during mobile phase.

- Prevents pressure build-up within the column.

- Extended life of Column.

- Guard columns have the additional benefit of using the same packing materials as the column to collect materials that would otherwise collect within the column.

Solvent Filters Features & Benefits

- Uniform Porosity

- Tortuous paths providing even flow

- Precise Manufacturing

- Strict Process and Quality Control

- Non-shedding

- Consistent & Repeatable Flow Through the filter

- Depth Filtration

- Repeatable Control

- Filter Integrity

- Extended life of HPLC and UHPLC systems and components.

What Porvair Can Offer

- Strong history in providing high-quality HPLC filters

- Meet customer custom designs offering a high-quality solution

- Onsite Citric Passivation

- Can be surface treated to improve inertness

- Lab Testing and material development available

- Latest manufacturing technologies

- Latest Inspection technologies

- Conforms to ISO9001

- ISO 4003 Æ Determination of Bubble Point Pore Size in Porous Sintered Metal